In the fascinating world of golf, a masterpiece is born through an intricate process known as crafting a golf club. From its humble beginnings to the final swing on the green, this article takes you on a captivating journey through the step-by-step process of creating a golf club. Explore the artistry and precision required, as well as the materials and techniques employed, to produce a club that brings joy and performance to every golfer. Get ready to immerse yourself in the captivating world of golf club craftsmanship!

Designing the Golf Club

When it comes to designing a golf club, there are several important factors to consider. The first step is determining the type of club that best suits your needs. Are you looking for a driver, a fairway wood, an iron, or a putter? Each club serves a different purpose on the golf course, so it’s essential to choose the right one for your game.

Once you have selected the club type, the next decision to make is the material for the clubhead. Common materials used in clubhead manufacturing include stainless steel, titanium, and carbon composite. Each material has its own unique properties and impacts the performance of the club, so it’s important to choose one that aligns with your playing style and skill level.

After deciding on the clubhead material, it’s time to determine the shape and weight of the clubhead. The shape and weight distribution affect the club’s forgiveness, launch angle, and spin rates. For example, a larger clubhead with a lower center of gravity is more forgiving and helps generate higher launch angles, while a smaller clubhead with a higher center of gravity offers more control and lower launch angles.

Clubhead Manufacturing

Once the design phase is complete, it’s time to move on to the manufacturing process. There are three primary methods for producing golf clubheads: casting, forging, and machining.

Casting involves pouring molten metal into a mold to create the desired shape of the clubhead. This method allows for intricate designs and precise weight distribution. On the other hand, forging involves shaping the clubhead by compressing and shaping the metal under high pressure. Forged clubheads tend to have a softer feel and are often preferred by more experienced golfers. Lastly, machining involves removing excess material from a solid block of metal to create the clubhead. This method provides precise control over the clubhead’s shape and weight.

Creating the Club Shaft

The club shaft plays a crucial role in the overall performance of the golf club. Choosing the right material is essential, as it affects the club’s feel, durability, and responsiveness. Common shaft materials include steel, graphite, and composite materials. Steel shafts offer excellent control and consistency, while graphite shafts are lighter and provide increased swing speed. Composite shafts combine the benefits of both materials, offering a balance of control and distance.

Once the shaft material is selected, it’s time to measure and cut the shaft to the desired length. The length of the shaft can impact the golfer’s swing mechanics, so it’s important to choose a length that suits your height, swing speed, and preference. After cutting the shaft, it goes through a shaping and tapering process to achieve the desired flex and stiffness characteristics.

Assembling the Golf Club

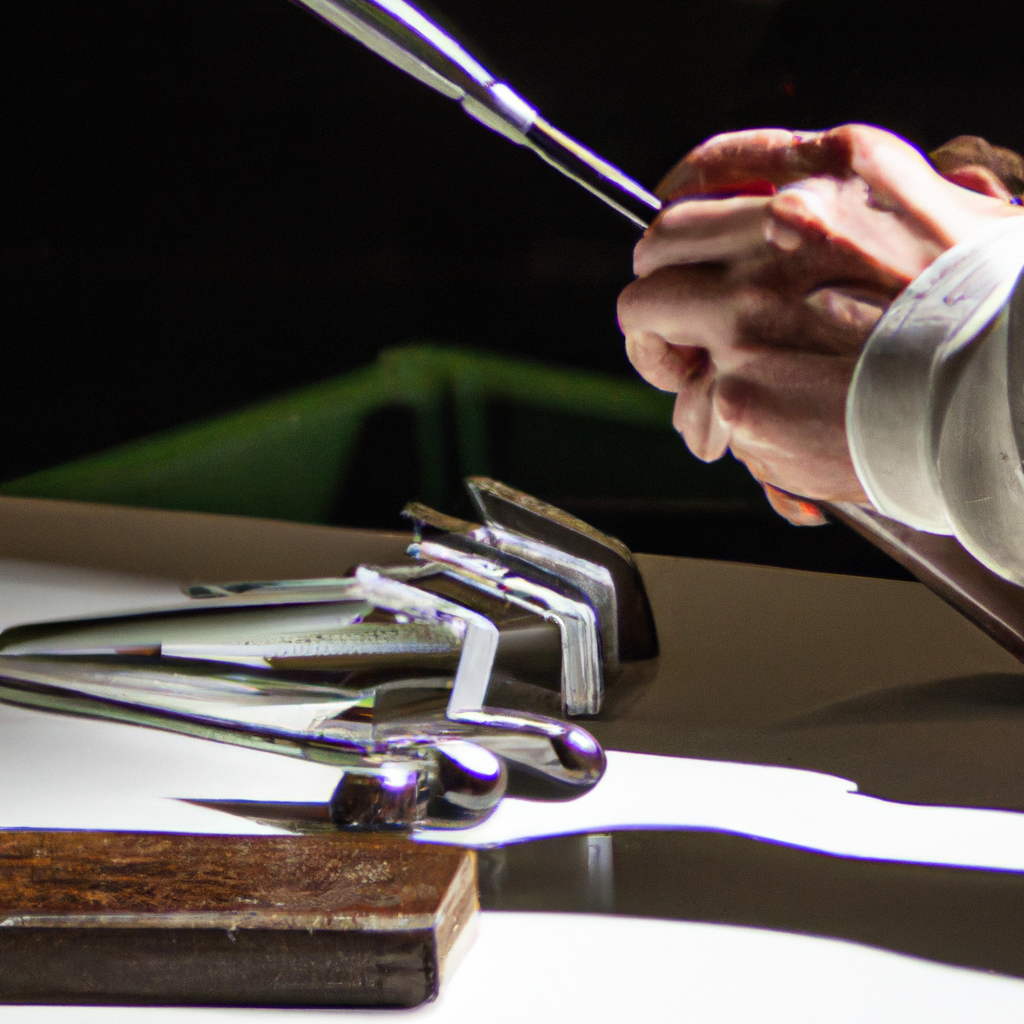

After the individual components are ready, it’s time to assemble the golf club. The first step is to prepare the clubhead and shaft for bonding. This involves cleaning and roughening the surfaces to ensure a strong and secure connection.

The next step is aligning and attaching the clubhead to the shaft. Depending on the clubhead design, this may involve bonding, welding, or using screws and hosels to secure the connection. Proper alignment of the clubhead is essential for optimal performance and consistency.

Once the clubhead is securely attached, the next step is to insert and secure the shaft. This often involves using epoxy or other adhesives to form a strong bond between the shaft and the clubhead. Careful attention to detail is required during this process to ensure the shaft is aligned correctly and securely fastened.

Grip Installation

The grip is an essential part of the golf club, as it provides the golfer with a comfortable and secure hold. When selecting a grip, there are a variety of materials to choose from, including rubber, synthetic compounds, and leather. Each material offers a different level of tackiness and feel, allowing golfers to customize their grip based on personal preference.

Before installing the grip, it’s important to apply grip tape to the shaft. Grip tape provides a secure base for the grip and prevents it from rotating during the golf swing. Once the grip tape is applied, the grip can be installed and aligned properly. This process often involves using solvents or adhesive solutions to ensure a tight and secure fit.

Club Balance and Swing Weight

Achieving the proper balance and swing weight is crucial for a golfer’s performance. Club balance refers to the distribution of weight throughout the club, while swing weight relates to how the club feels during the swing.

Measuring club balance involves determining the center of gravity (CG) and ensuring it aligns with the desired specifications for the club. This is often achieved by adding or removing weight from certain areas of the clubhead or the grip end of the shaft.

Swing weight, on the other hand, is determined by the club’s overall weight distribution. Adding or removing weight from the clubhead, shaft, or grip can help adjust the swing weight to match the golfer’s preference. Fine-tuning the club’s center of gravity and swing weight allows for optimal performance and a more comfortable swing.

Club Finishing

After the club components are assembled and balanced, it’s time to give the golf club its final finish. The clubhead goes through a sanding and polishing process to achieve a smooth and aesthetically pleasing surface. This enhances the club’s appearance and reduces the risk of corrosion or wear over time.

To protect the clubhead, a protective coating is applied. This coating not only adds a layer of durability but also helps maintain the club’s performance characteristics. Additionally, branding and engravings can be added to showcase the club’s manufacturer or personalized details.

Quality Control

Before a golf club can make its way to the golfer’s hands, it goes through a rigorous quality control process. Inspecting the clubhead involves checking for any manufacturing defects, such as cracks, dents, or irregularities. This ensures that each club meets the manufacturer’s standards and provides consistent performance.

Testing the shaft’s flexibility helps ensure that it aligns with the desired specifications. Using specialized equipment, the shaft is subjected to various bending and twisting forces to assess its response and ensure it falls within the specified flex rating.

Checking the club’s weight and dimensions is another crucial step in quality control. Each club must meet the designated weight range and dimensions specified by the manufacturer to ensure consistency and fair play.

Customization Options

Golf clubs can be customized to suit individual preferences and playing styles. Personalizing club graphics allows golfers to add their own touch to the club’s appearance. This can include custom colors, logos, or even personalized engravings.

Offering different shaft and grip options allows golfers to tailor their clubs to their specific needs. For example, golfers can choose between different shaft flexes to match their swing speed, or select a grip size that feels most comfortable in their hands.

Customizing club length and lie angle ensures that the clubs fit the golfer’s physical attributes and swing mechanics properly. This can greatly impact a golfer’s consistency and accuracy, making custom fitting an important consideration for serious golfers.

Post-Production Services

Even after a golf club is purchased, there may be a need for post-production services. Repairing and refurbishing clubs can restore old or damaged clubs to their original condition. This can include replacing broken components, adjusting club balance, or refinishing worn-out surfaces.

Re-gripping and re-shafting services are also commonly offered. Over time, grips can wear out or lose their tackiness, and shafts may need to be replaced due to damage or changes in personal preference. These services allow golfers to extend the life of their clubs and maintain optimal performance.

Custom fitting and swing analysis services help golfers fine-tune their equipment to maximize their potential on the golf course. By analyzing a golfer’s swing mechanics and physical attributes, experts can recommend the most suitable club specifications and adjustments to enhance performance.

Crafting a golf club is a complex and intricate process that involves careful consideration of various factors. From initial design to quality control and customization options, manufacturers strive to produce clubs that meet the unique needs and preferences of golfers. By understanding the craftsmanship behind a golf club, you can appreciate the attention to detail and dedication that goes into creating these essential tools for the game.