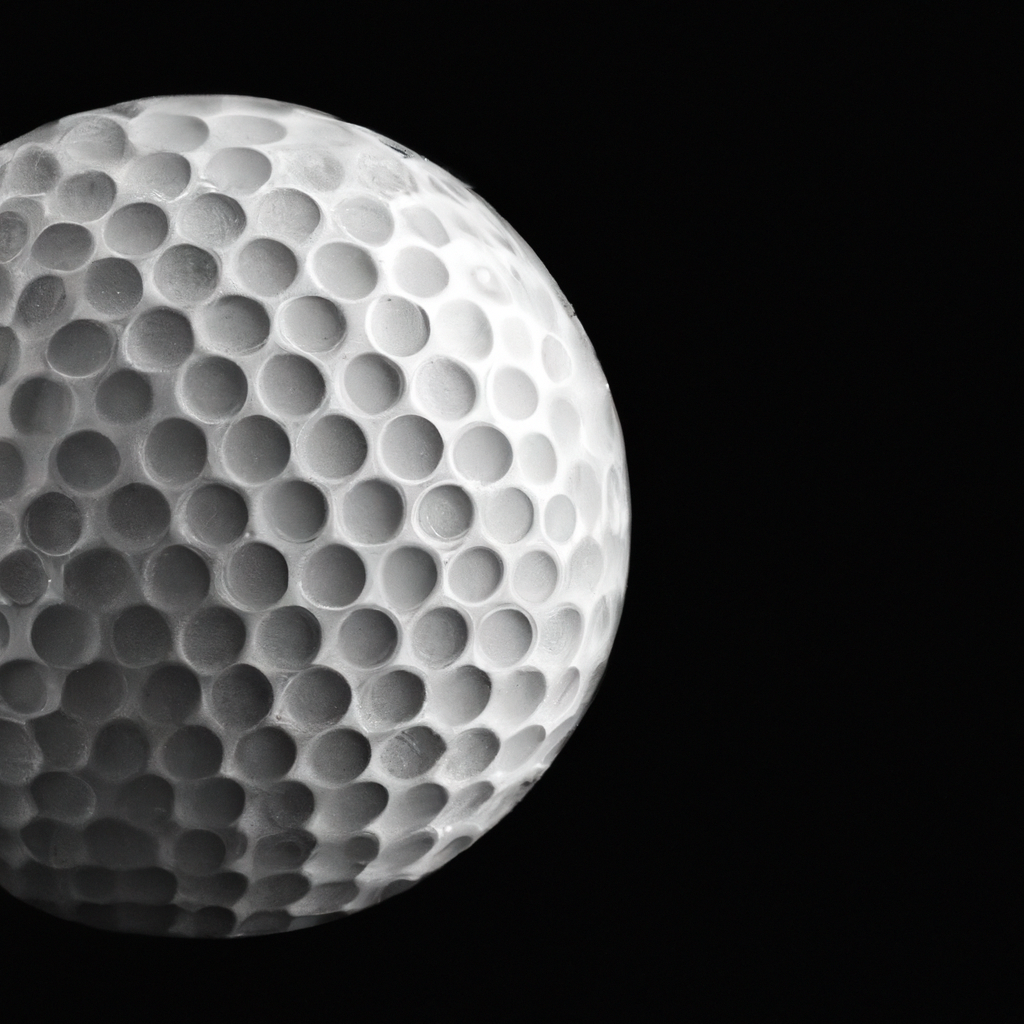

Imagine hitting a golf ball on a sunny day, watching it soar through the air with grace and precision. Have you ever wondered why golf balls have those little dimples on their surface? These dimples are not merely decorative; they serve a crucial purpose in enhancing the ball’s flight and accuracy. But how many dimples are there on a golf ball? Join us as we unravel the mystery behind these tiny indentations and discover their impact on the game of golf.

The History of Dimples on a Golf Ball

Early Golf Balls

In the early days of golf, the sport was played with wooden balls, which lacked the aerodynamic properties necessary for optimal distance and accuracy. As the game evolved, golfers began experimenting with different materials, such as feather-filled leather pouches, to create more efficient balls. However, it wasn’t until the mid-19th century that the concept of adding dimples to a golf ball emerged.

The Discovery of Dimples

The discovery of dimples on a golf ball is often attributed to a golfer named William Taylor, who noticed that damaged and scratched balls seemed to have a smoother flight and travelled farther than their clean counterparts. Intrigued by this observation, Taylor began deliberately creating dents and depressions on the surface of his balls, which led to a significant improvement in their performance. This accidental discovery laid the foundation for the future use of dimples on golf balls.

Evolution of Dimple Patterns

After the initial discovery of the benefits of dimples, golf ball manufacturers began experimenting with different dimple patterns to further enhance the ball’s aerodynamic properties. The early dimple patterns were simple and haphazard, lacking consistency and precision. However, as scientific understanding and manufacturing capabilities improved, golf balls started featuring more sophisticated dimple designs, optimized to reduce drag and enhance lift.

The Science Behind Dimples

Aerodynamics of a Golf Ball

To understand the science behind dimples, it is essential to grasp the basics of aerodynamics. When a golf ball is in flight, it experiences two primary aerodynamic forces: lift and drag. Lift helps the ball stay airborne and allows it to achieve greater distances, while drag acts as a resistance force that slows down the ball’s forward motion.

The Boundary Layer

The boundary layer is a thin layer of air that clings to the surface of the golf ball as it moves through the air. When a golf ball without dimples is in flight, the boundary layer becomes turbulent, increasing drag and reducing lift. Conversely, when a ball with dimples is in motion, the dimples disrupt the airflow, causing the boundary layer to remain laminar, resulting in reduced drag and increased lift.

Lift and Drag Forces

Dimples on a golf ball affect lift and drag forces by altering the flow of air around the ball. The dimples create turbulence in the boundary layer, effectively delaying the separation of airflow and allowing the ball to maintain a more stable flight. This phenomenon enables the ball to generate more lift and reduce drag, leading to increased distance and accuracy on the golf course.

The Role of Dimples in Golf

Improved Distance and Accuracy

One of the primary benefits of dimples on a golf ball is the significant improvement in distance and accuracy. By reducing drag, dimples allow the ball to maintain its velocity for a longer duration, enabling it to cover more distance with each shot. Additionally, the stability provided by the dimples helps the ball maintain a steady trajectory, resulting in improved accuracy and consistency.

Effect on Spin and Trajectory

Dimples also play a crucial role in controlling the spin and trajectory of a golf ball. The airflow disruption caused by the dimples creates a lifting force on the ball, which contributes to backspin. This backspin allows the ball to stay in the air longer and provides golfers with greater control over the ball’s flight path. Dimple design variations can further optimize this effect, allowing golfers to manipulate the ball’s behavior based on their playing style and preferences.

Differences in Dimple Designs

The choice of dimple design can have a significant impact on a golf ball’s performance. Dimple designs can vary in terms of size, shape, depth, and distribution. Some dimple designs prioritize reduced drag, while others focus on enhancing lift and stability. Golfers can choose a ball with dimples that align with their playing style and environmental conditions, ensuring they get the most out of their game.

Factors Affecting Dimple Performance

Dimple Size and Shape

The size and shape of dimples directly influence a golf ball’s aerodynamic performance. Generally, larger and deeper dimples will produce greater lift, while smaller and shallower dimples reduce drag. Additionally, different dimple shapes, such as circular, hexagonal, or square, can affect the flow of air around the ball and impact its flight characteristics.

Dimple Depth and Distribution

The depth and distribution of dimples across the surface of a golf ball play a crucial role in its overall performance. Dimple depth affects the interaction between the air and ball surface, while the distribution of dimples determines how airflow is disrupted, influencing lift and drag forces. Manufacturers meticulously engineer the placement and arrangement of dimples to optimize their impact on the ball’s flight.

Surface Roughness

The roughness of a golf ball’s surface, often created by the indentations of dimples, also affects its aerodynamic properties. A rougher surface promotes the formation of a more turbulent boundary layer, increasing drag but potentially enhancing lift. Optimal surface roughness is a delicate balance that manufacturers consider when designing golf balls to ensure optimal performance in various playing conditions.

Manufacturing of Golf Balls

Injection Molding Process

The manufacturing process of golf balls typically involves injection molding. A two-piece golf ball consists of a solid inner core and a thermoplastic cover. The inner core is formed using a combination of materials, such as rubber and synthetic compounds, to achieve the desired compression and feel. The cover, which includes the dimples, is made by injecting heated thermoplastic material into a mold that creates the dimple pattern.

Formation of Dimple Pattern

During the injection molding process, the molds used are customized with the desired dimple pattern. The molten thermoplastic material is injected into the mold, filling the individual dimples and creating the pattern directly on the surface of the ball. The precision and consistency of the molding process are critical to ensuring uniform dimple dimensions and distribution.

Quality Control Measures

To maintain the integrity and performance of golf balls, manufacturers implement strict quality control measures throughout the manufacturing process. Automated inspections are conducted to check for any deformities or inconsistencies in the dimple pattern, as well as to verify the compression and construction of the inner core. Stringent quality control ensures that every golf ball meets the required standards for performance and durability.

Innovation and Advancements

Dimple Designs for Specific Purposes

In recent years, golf ball manufacturers have introduced specialized dimple designs for specific purposes. Some designs prioritize reducing drag to achieve longer distances, while others focus on enhancing lift for better control and accuracy. These advancements allow golfers to choose a ball that aligns with their playing style, preferences, and environmental conditions, taking their game to new heights.

Non-Circular Dimples

Traditionally, golf ball dimples were circular in shape. However, advancements in technology and research have led to the development of non-circular dimple designs. These innovative dimple shapes further enhance ball flight characteristics, providing golfers with additional options for optimizing performance. By exploring non-traditional dimple patterns, manufacturers are pushing the boundaries of aerodynamic efficiency in golf balls.

Future Technologies

The world of golf ball technology is continually evolving, with a constant focus on maximizing performance. Future advancements may include the incorporation of advanced materials, such as nanotechnology, to enhance the aerodynamic properties of golf balls. Additionally, advancements in computer modeling and simulations allow manufacturers to simulate and test various dimple designs and configurations, leading to more optimized and tailored golf balls.

Dimple Myths and Misconceptions

More Dimples Mean Better Performance

Contrary to popular belief, the number of dimples on a golf ball does not necessarily correlate to better performance. While it is true that more dimples can result in reduced drag, the overall performance of a golf ball heavily depends on the specific dimple design, size, shape, and distribution. Golf ball manufacturers carefully engineer dimple patterns to optimize performance, and the number of dimples is just one factor among many.

Paint and Dimples

Another common misconception about dimples on golf balls is related to the impact of paint. Some golfers believe that paint fills the dimples, negating their aerodynamic benefits. However, manufacturers carefully apply paint to golf balls, ensuring that it does not interfere with the dimple depths or disrupt the airflow over the ball’s surface. The layer of paint is thin enough not to hinder the dimples’ effectiveness.

The Perfect Dimple Pattern

Many golfers search for the elusive “perfect” dimple pattern that guarantees the best performance. However, there is no universally perfect dimple pattern that suits all golfers and playing conditions. The optimal dimple pattern varies depending on factors such as swing speed, launch angle, and environmental conditions. It is essential for golfers to find a dimple pattern that works harmoniously with their game and unique requirements.

Dimple Effects on Green and Environmental Sustainability

Damage to the Green

One potential concern regarding dimples on golf balls is the impact they can have on the green. When a golf ball with dimples strikes the green, the indentations can create small divots or damage the grass. However, golf course maintenance practices, such as regularly aerating the greens and strategically placing pin positions, help mitigate the effects of ball impacts, ensuring the greens remain in excellent condition.

Biodegradable Golf Balls

Addressing environmental sustainability concerns, golf ball manufacturers have been developing biodegradable options. These eco-friendly golf balls aim to reduce the environmental impact caused by lost or discarded balls. Biodegradable materials used in their construction break down naturally over time, minimizing harm to the environment.

Reducing Environmental Footprint

In addition to biodegradable options, the golf industry is actively seeking ways to reduce its overall environmental footprint. Manufacturers are using sustainable materials and implementing eco-friendly manufacturing practices. Furthermore, initiatives such as recycling programs for used golf balls and the use of renewable energy in manufacturing facilities contribute to minimizing environmental impact.

Other Uses of Dimple Technology

Dimpled Surfaces in Other Industries

The aerodynamic benefits of dimpled surfaces have extended beyond the world of golf. Dimple technology has found applications in various industries, such as automotive, aerospace, and even cycling. These industries leverage the disruptive effects of dimples on airflow to reduce drag and improve efficiency in their respective products. Dimples are no longer limited to golf balls, becoming a source of inspiration for innovation in other fields.

Inspiration for Innovation

The discovery and development of dimple technology on golf balls have sparked innovation in aerodynamics and engineering. Scientists and engineers continue to study and explore the principles behind dimples, applying their findings to create more efficient designs in various industries. The evolution and optimization of dimple technology in golf have paved the way for advancements in other areas.

Dimples in Sports Equipment

The benefits of dimples are not limited to golf balls alone. Dimpled surfaces have found their way into other sports equipment, such as soccer balls and tennis balls. Similar to golf balls, these sports balls utilize dimples to enhance their aerodynamic properties, resulting in improved performance, stability, and control during play.

Conclusion

Impact of Dimples in Golf

The inclusion of dimples on golf balls has revolutionized the sport, significantly enhancing distance, accuracy, and control. Golfers of all skill levels can benefit from the aerodynamic advantages provided by the dimples, allowing them to achieve greater distances and improved accuracy on the course.

Continued Research and Development

The history of dimples on golf balls is a testament to the importance of research and development in the golf industry. Manufacturers continually invest in studying aerodynamics, materials, and manufacturing techniques to push the boundaries of performance. Ongoing research ensures that golfers have access to the latest advancements and innovations in ball technology.

Role of Dimple Technology in Golf Industry

Dimple technology has become an integral part of the golf industry, shaping the design and performance of modern golf balls. The science behind dimples has unlocked new possibilities for golfers, providing them with improved distance, accuracy, and customization options. As technology continues to advance, dimple technology will continue to evolve, further enhancing the game of golf for generations to come.